Data-driven organizations that embrace Digital Transformation possess immense potential for innovation and enhanced efficiency. However, it is also crucial to leverage that potential for the good of the planet and turn your sustainability ambitions into measurable and tangible results.

Feel free to share your ideas, thoughts, and insights regarding practical applications, best practices, and examples of how data can be harnessed to reduce environmental footprints. Remember, even the tiniest actions can yield a huge impact.

Let’s help our precious planet by inspiring each other!

Energy Management in data centers and buildings.

Utilizing data to optimize energy consumption in buildings, factories, and other facilities, by implementing smart sensors, meters, and IoT devices to collect real-time energy data.

Through analysis of this data, it could be possible to identify areas of energy waste, optimize energy usage patterns, and make informed decisions on energy-efficient technologies and practices.

To an extent heat generated by data centers could be transferred to heat other areas of a building during cold weather times.

USE CASE : smart powering of on-prem devices used for ad-hoc services

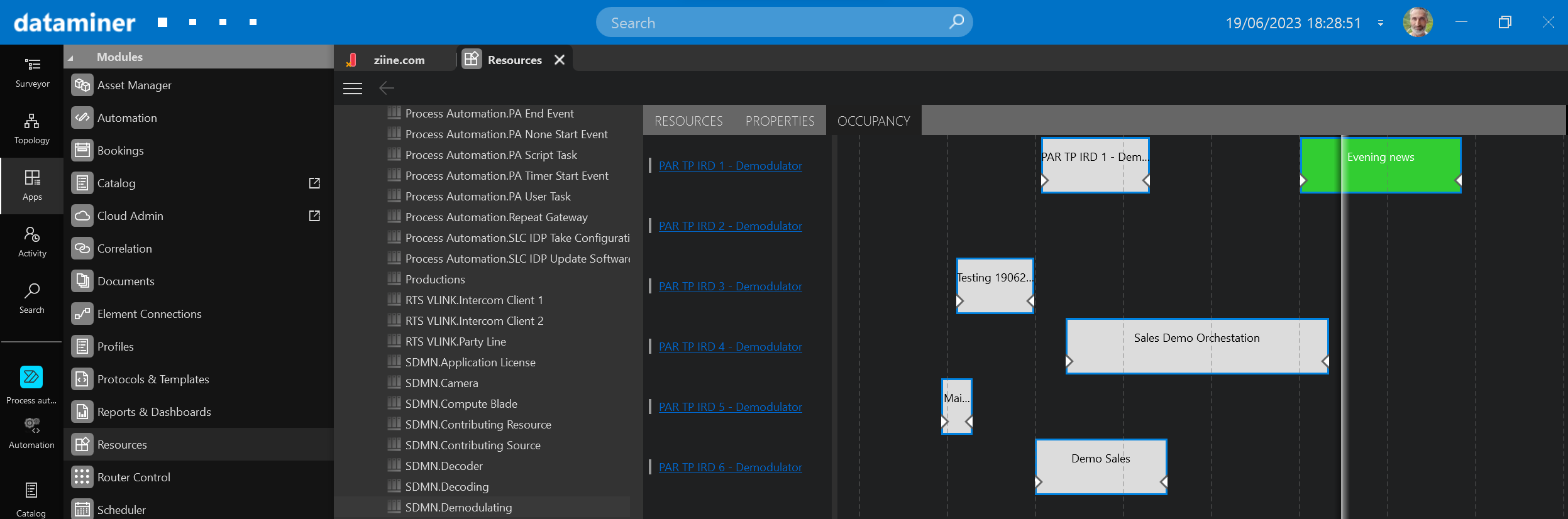

With DataMiner we do a lot of resource planning & orchestration for ad-hoc services (e.g. MCRs, contribution links for sports events, etc.). This means that DataMiner has perfect visibility on when resources are used, and when they are idle.

This is undoubtedly also an opportunity to reduce footprint. Because in many environments, all this equipment is fully powered up and running 24/7. As part of the orchestration, DataMiner could power up and down that equipment, or leverage hibernation features to put them in a low power mode if available. PDUs (Power Distribution Units) could be used for that, where available WOL (Wake On LAN) maybe, etc.

This would reduce power consumption of the device itself, but also the power needed to cool the facility (interesting fact: on average, cooling of these facilities represents 40% of the overall power consumption, so you pay almost as much to cool a piece of equipment as you do to power it apparently).

Switch vendors also promote a list of features to reduce power consumption (you can put an idle switch in standby mode, idle switch ports can be set to standby mode, unused network uplinks can be set to lower power hibernation mode, etc.). I’ve already heard of disabling ports when no scheduled services are running, to improve the security posture, but this would also reduce power consumption. Double win.

USE CASE : smart control of heating of dishes in satellite teleports

I saw a nice and simple, but very effective automation with DataMiner, done by a major teleport operator. The dishes in a teleport have a heating system in area’s where it can freeze and/or snow. Because the latter could affect the quality of the uplink/downlink.

Before DataMiner was in place, those systems were simply manually switched on or off, i.e. an all or nothing type of situation. And this while these systems can consume quite a bit of power, as they need to heat quite big surfaces.

With DataMiner they implemented some basic logic to switch the heating systems on and off periodically at different time intervals, to save quite a bit on consumption for situations where full heating was definitely an overkill. Also they cycled from one antenna to the other, to have more continuous consumption, instead of high peak demands.

I believe they also had other plans to further automate it with data from their weather station, to make sure that it was only used when needed (because in the past it was often switched on way too long).

That is really interesting and reminded me of Starlink dishes that have a Snow Melt mode.

Not sure how it works or what sensors they use but I guess it is a use case that can be expanded to more things where proper temperature management leads to more efficiency like telecommunications or battery management

Datacenters consume large quantities of energy every year. Global data center electricity use in 2021 was 220-320 TWh2, or around 0.9-1.3% of global final electricity demand.

Using DataMiner, clients can make more efficient use of cloud resources, reduce costs and ultimately help drive down the environmental cost.

Occasional use of cloud functions to deliver services can be optimized using DataMiner orchestration capabilities compatible with multiple cloud providers such as AWS and Azure.

This use case, Amazon AWS EC2 – manage compute capacity and cloud applications with DataMiner, discusses how DataMiner can be used to manage compute capacity and cloud applications on AWS EC2. It explains that DataMiner can help optimize resource usage, reduce costs, and improve application performance. It also includes a case study demonstrating the benefits of using DataMiner for managing cloud applications on EC2.

Reducing the number of site visits for your technicians

You can structure your equipment into views that represent a location/region, so you can validate all the alarms within that view/region and send your technician out with equipment for all the alarms under that view.

You could also take it a step further and use the correlation application within DataMiner to group alarms in a smart way, so you can make the right conclusion on what device might be leading to these alarms. This way the technician can make the right decision on what equipment is needed without taking too much with him, leaving maybe sufficient space for the next stop.

Reducing the number of times you need to send a technician on-site will not only save you time and money, it will also reduce your impact on the environment

Indeed – in general, anything that can be done towards being more efficient and proactive in your field support operation, will contribute also to your footprint reduction. A double win, reducing cost considerably and reducing foot print.

The fact that this can be quite considerable is illustrated by the following real-life use case: Telenet, based on the DataMiner EPM solution, implemented a pro-active field maintenance solution, and effectively reduced their truck roll-outs with 20.000 / year through the initiative. This is a huge cost-saving, but indeed also a very considerable footprint reduction.

Organizations can implement data-driven solutions for e-waste management that allow tracking and analysis of equipment lifecycle, upgrades, and repair data.

With this data, they can promote better repairability, upgradability, and recycling practices, as well as, identify potential environmental factors (amongst others) for a lower mean time between failure of certain devices when compared with others of the same type.

Having this data could also help in future purchasing decisions along with “putting pressure” on vendors to adopt better environmental practices and not continue the trend of “planned obsolescence”.

Also, this data can be leveraged to perform predictive and preventative maintenance by using features such as DataMiner’s monitoring and analytics to predict equipment anomalies and failures based on equipment performance and repair/replacement history.

As an example, Framework https://frame.work/ is a company whose business model is to sell modular laptops that can be configured, upgraded, and repaired by the end user.

Indeed – one of the unique capabilities of DataMiner is to source data from pretty much any imaginable source, and the first step is to focus on collecting all possible relevant data related to the topic. That could include integrating with Power Distribution Units (PDUs), environmental systems like cooling, etc. And when the data is not available, there’s an abundance of very affordable sensors available to measure currents, voltages, temperatures, etc. But the first step is definitely to start looking at consolidating all the data in DataMiner, to unify it in the DataMiner digital twin, and then you can start working on the various use cases that can help you reduce your environmental footprint.