integration Use Case

Field power supply manager for cable companies

SCTE

This DataMiner solution manages thousands of field power supplies across a vast territory allowing remote testing, advanced diagnostics, and fault forecasting. As a result, significant savings have been achieved in terms of truck rolling, ensuring timely deployment of the appropriate teams, and fostering improved communication among crews, thus enhancing operational efficiency.

The solution supports bi-directional communication between DataMiner and HMS Power Supplies with both IPv4 and IPv6. It also facilitates monitoring, remote testing, capacity planning, and proactive external network maintenance.

USE CASE DETAILS

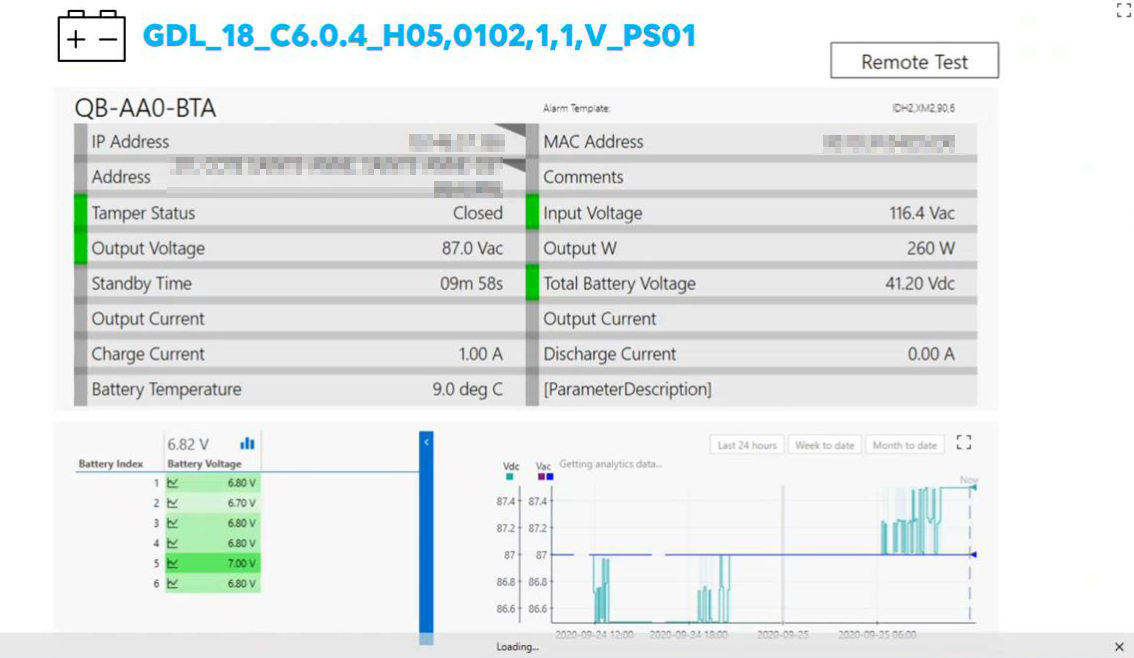

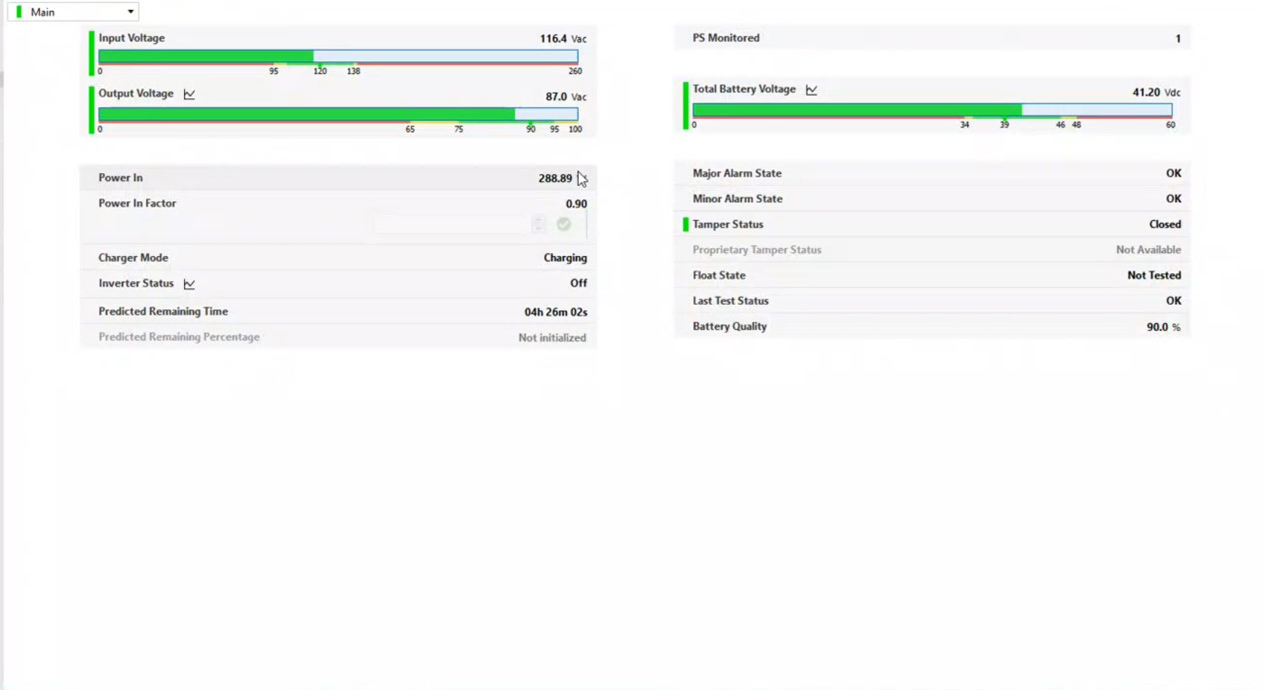

All available parameters from the HMS are included by default to provide the main KPIs.

All available parameters from the HMS are included by default to provide the main KPIs.

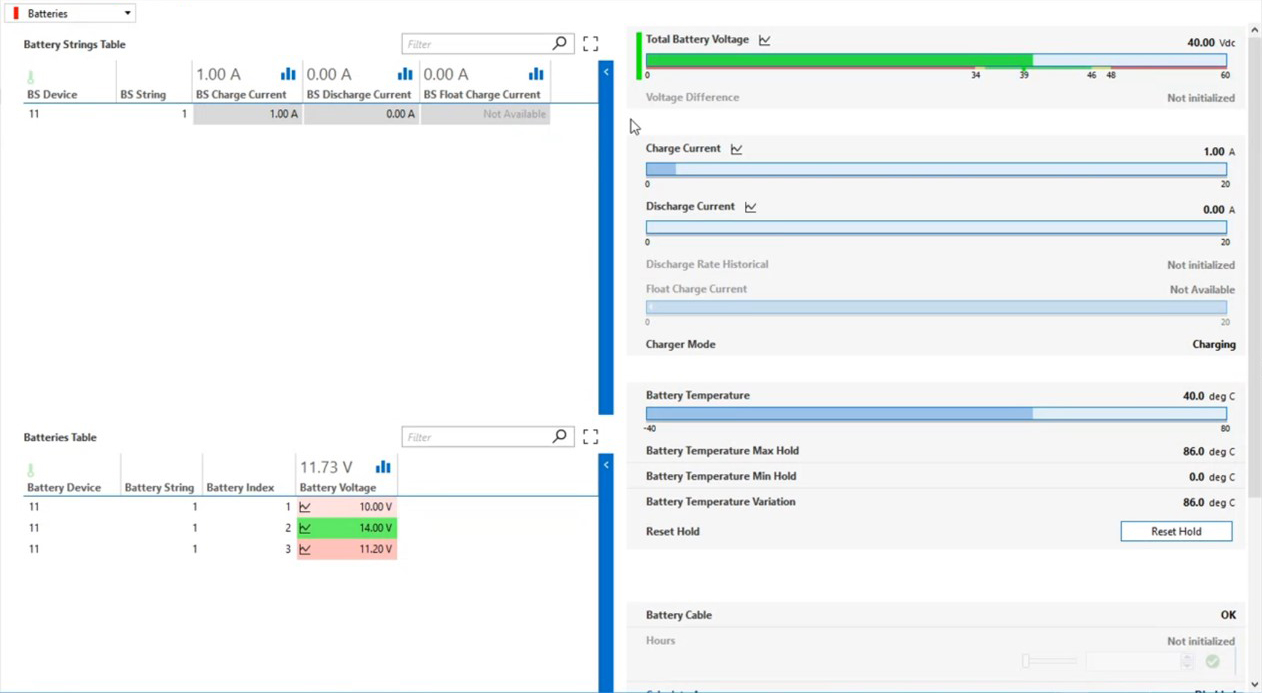

Battery measurements are important to determine the backup capacity of the power supply.

Battery measurements are important to determine the backup capacity of the power supply.

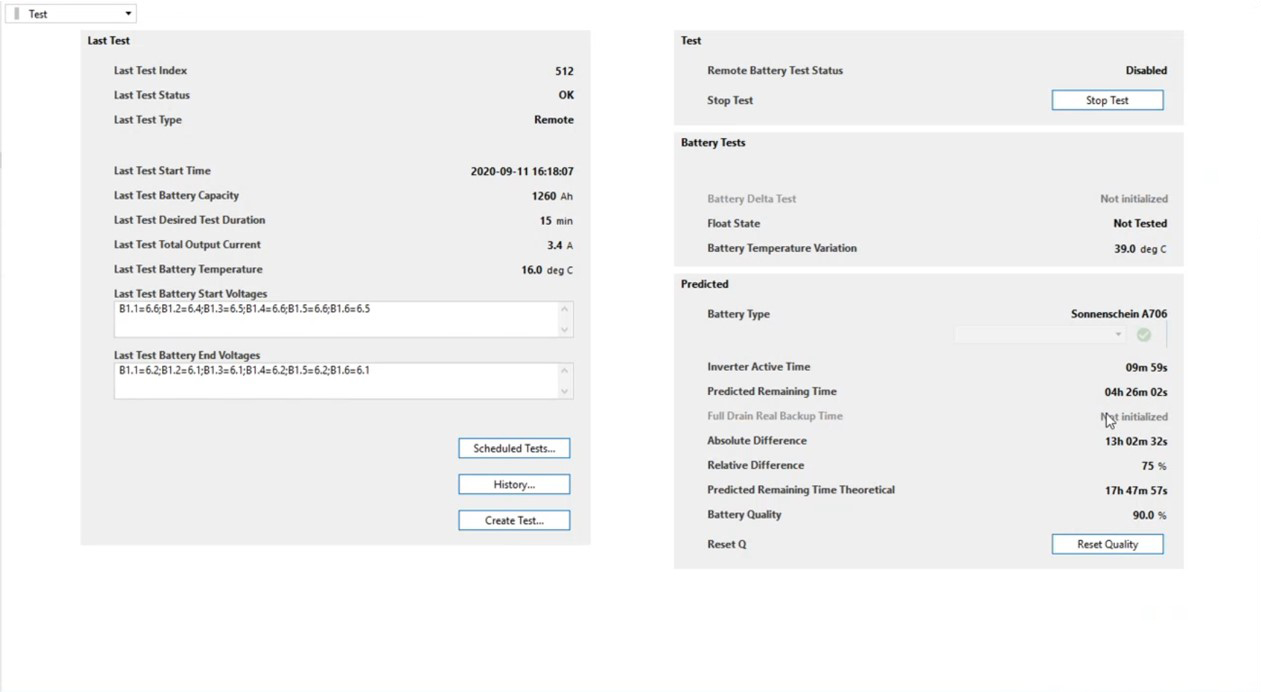

Remote testing is possible from DataMiner to calculate an effective predictive remaining time (PRT) for backup. The theoretical remaining time is calculated based on information from the battery vendor and the parameters read from the transponder. After a remote test, DataMiner calculates the PRT using the discharge curve and compares with the theoretical remaining time to give a difference between them and be able to trigger any maintenance action.

Remote testing is possible from DataMiner to calculate an effective predictive remaining time (PRT) for backup. The theoretical remaining time is calculated based on information from the battery vendor and the parameters read from the transponder. After a remote test, DataMiner calculates the PRT using the discharge curve and compares with the theoretical remaining time to give a difference between them and be able to trigger any maintenance action.

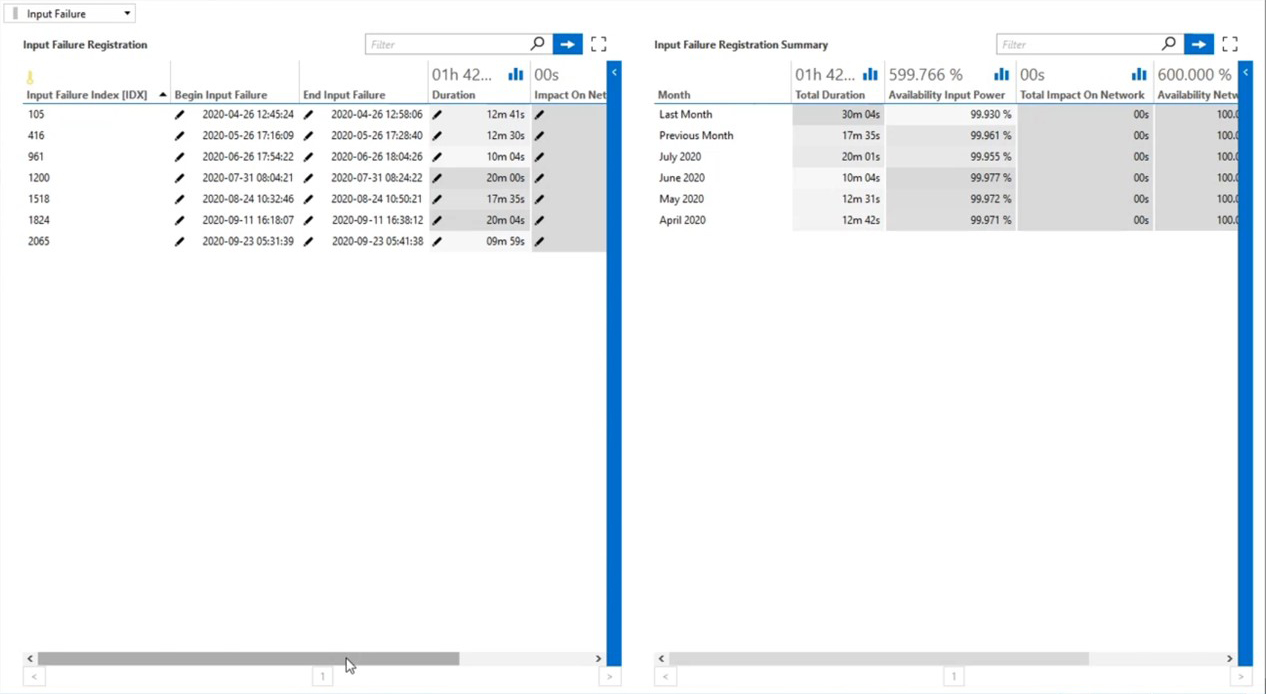

Input registration failure per power supply is included and the availability of the network is calculated.

Input registration failure per power supply is included and the availability of the network is calculated.

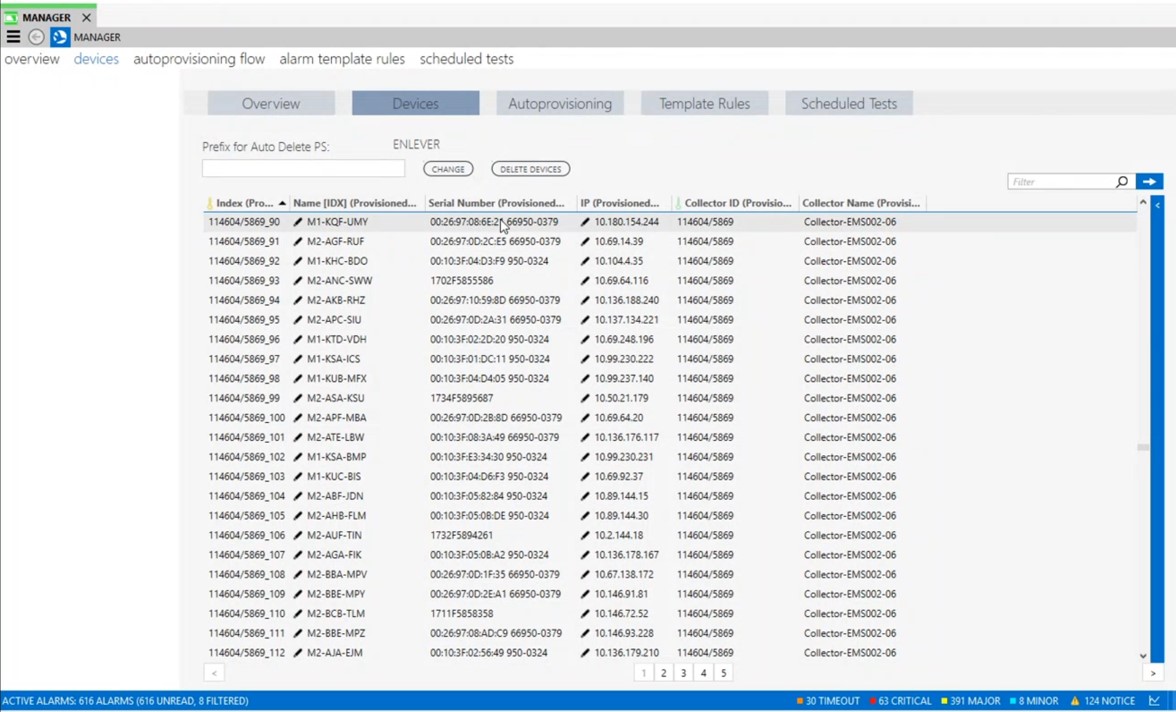

A manager application allows bulk or group control to assign alarm templates or schedule tests.

A manager application allows bulk or group control to assign alarm templates or schedule tests.

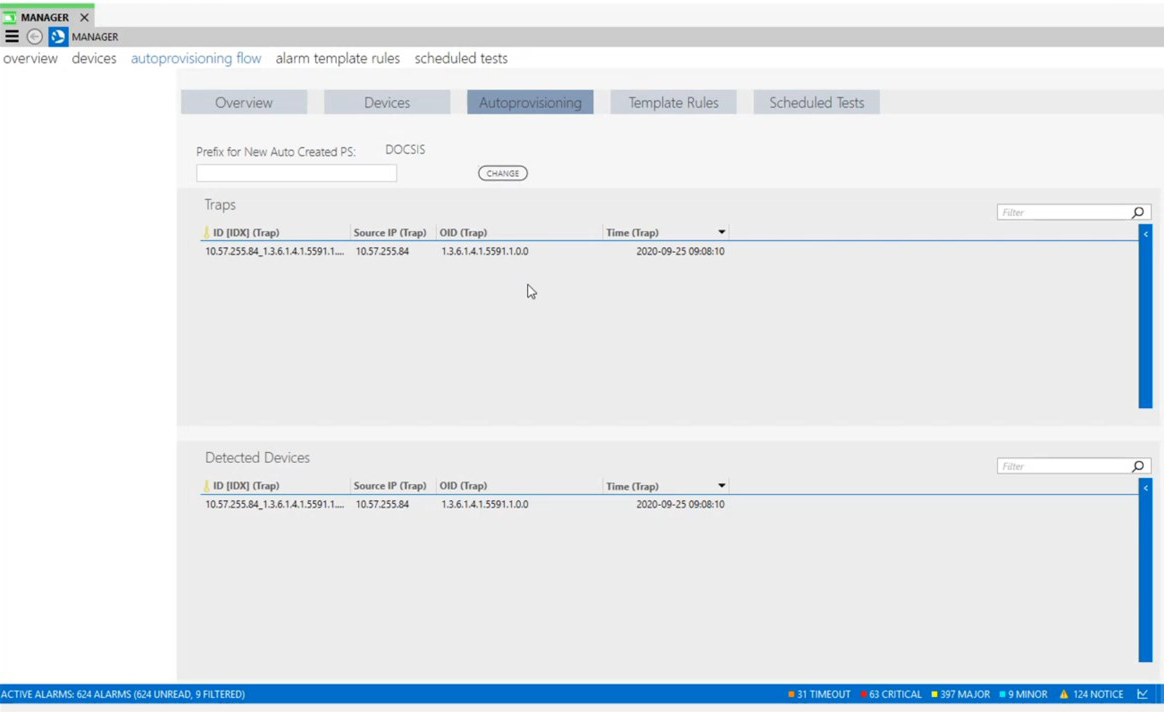

Automatic provisioning is included in the manager app to easily create a new element in the system when a device is detected.

Automatic provisioning is included in the manager app to easily create a new element in the system when a device is detected.

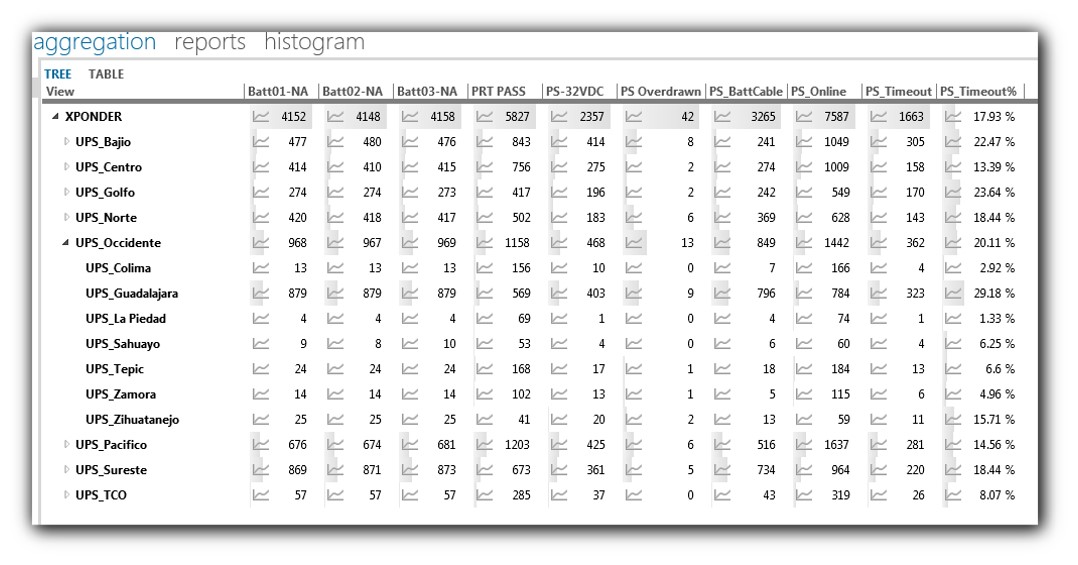

KPIs can be presented in many different ways using other DataMiner modules such as the aggregation engine.

KPIs can be presented in many different ways using other DataMiner modules such as the aggregation engine.

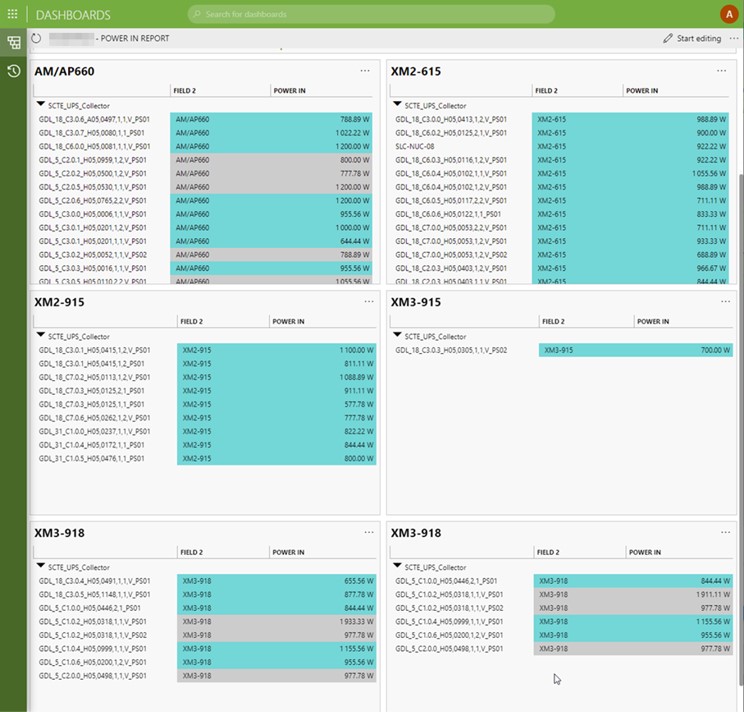

KPIs can be presented in many different ways using other DataMiner modules such as the Dashboards app.

KPIs can be presented in many different ways using other DataMiner modules such as the Dashboards app.