example Use Case

Fully automated end-to-end network configuration and service provisioning

This use case focuses on a suite of fully automated processes for the end-to-end provisioning and lifetime support of a network serving approximately 2.5 million subscribers using a DOCSIS distributed access architecture.

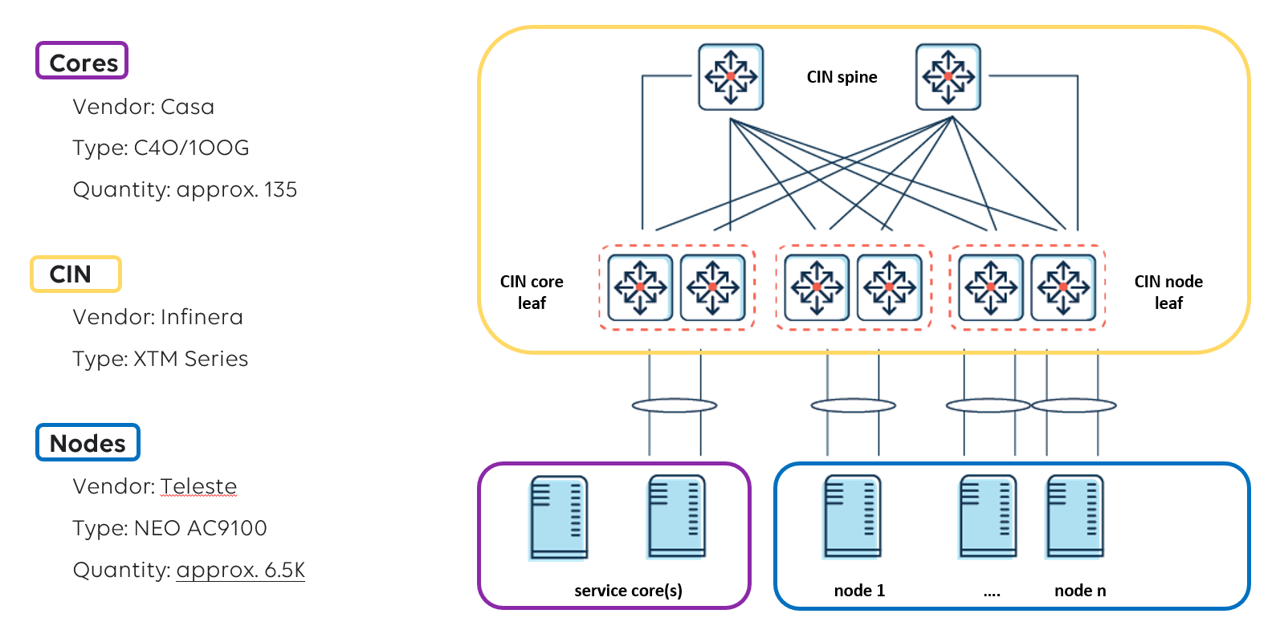

Above, you can see the network’s high-level architecture and core components overview. The Casa systems C40/C100G primary cores, reused from the previous centralized architecture, interface with new Teleste NEO AC9100 Remote Phy nodes across a converged interconnect network (CIN) implemented using the Infinera XTM Series. The element quantities range from about 135 primary cores to 6500 node elements outside the plant.

These are the main benefits of this setup:

– Minimum OPEX: If you just count the labor savings associated with the initial provisioning and add to this for example 40 minutes per service update (assuming that this affects 20 % of the installed base per year or is performed on the entire footprint once every 5 years), you get to 2 hours and 40 minutes over 5 years. For this customer, this already amounts to approximately 17,290 hours and over 8.27 man-years. And then you haven’t even taken the extras into account that will be associated with for example RxD replacements following a failure or core migrations associated with the introduction of virtual cores. The actual cost savings are evidently directly linked to the labor cost for the operator, but there are also the savings that are linked to the number of nodes that will be deployed. With about 6500 nodes to be deployed and operated, the cost savings associated with the use of fully integrated workflows for end-to-end provisioning are massive. What is more, larger MSOs will benefit from this even more than this operator already does.

– Reduced time to service: The actual time savings will differ from one workflow to another and could also change slightly from one operator to another. Nevertheless, nothing can beat this integrated setup when it comes to the time to service. Only few operators have published detailed information about the actual time savings associated with every workflow, but there are publications confirming that these can amount to more than 2 hours for things like initial provisioning and a change in forward/reverse split. Similar savings can reasonably be expected for an RxD replacement. The fully automated provisioning clearly has a very positive impact on both the initial time to service and the service restoration time.

– Maximum security: CIN ports are only opened when the field technician is already on site unboxing the product, and they are closed immediately upon the move towards another port. With the automated process using templates that are tested up front, compliance with security rulings increases immensely. It is simply impossible to achieve similar security levels in any other manner.

– Increased availability: The fully automated end-to-end provisioning, which uses templates that have been tested up front for correctness and compatibility, reduces the risk of failure and the exposure to human error. This already minimizes the risk that truck rollouts may be needed because of non-conforming installations and configurations. The added possibility to immediately reprovision in case there is (partial) loss of configuration increases the network/service availability and resiliency even further.

USE CASE DETAILS

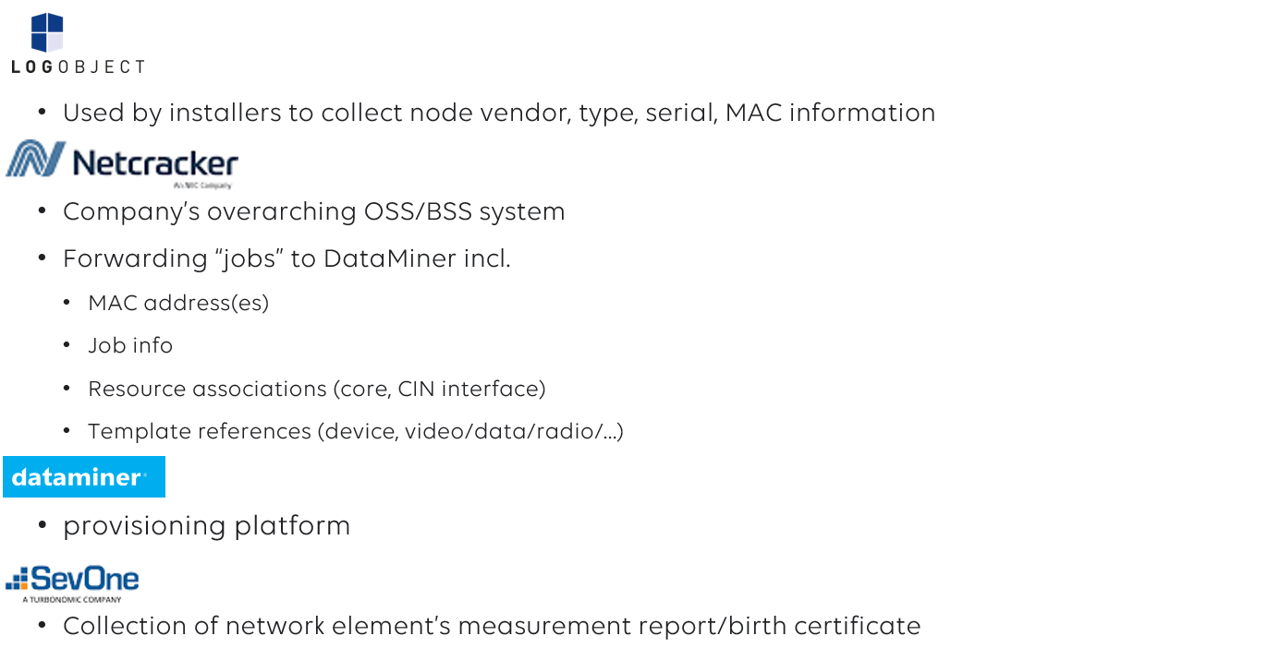

DataMiner is in charge of the actual provisioning, i.e. the implementation of fully automated (re-)provisioning processes dictating the integration with all other involved operational support systems (OSS). Netcracker, as the company’s overarching OSS/BSS system, not only controls the initial rollout, but also interacts with the LogObjects platform used by the outside plant technicians to collect and forward element information such as the type and the serial and MAC addresses at the time of the node’s installation or replacement.

Once all data required for the provisioning activity is available, the same system will also forward the actual provisioning request to DataMiner, including full details on the type of provisioning, the element(s) in scope, the templates to be used, and the timing. In addition to performing the network and node provisioning activities, DataMiner will in turn also trigger SevOne for the collection of the element’s birth certificate and initial performance report.

A provisioning job will only be closed when DataMiner confirms the successful execution and provides the test report/birth certificate that needs to be entered in the OSS database.

DataMiner is in charge of the actual provisioning, i.e. the implementation of fully automated (re-)provisioning processes dictating the integration with all other involved operational support systems (OSS). Netcracker, as the company’s overarching OSS/BSS system, not only controls the initial rollout, but also interacts with the LogObjects platform used by the outside plant technicians to collect and forward element information such as the type and the serial and MAC addresses at the time of the node’s installation or replacement.

Once all data required for the provisioning activity is available, the same system will also forward the actual provisioning request to DataMiner, including full details on the type of provisioning, the element(s) in scope, the templates to be used, and the timing. In addition to performing the network and node provisioning activities, DataMiner will in turn also trigger SevOne for the collection of the element’s birth certificate and initial performance report.

A provisioning job will only be closed when DataMiner confirms the successful execution and provides the test report/birth certificate that needs to be entered in the OSS database.

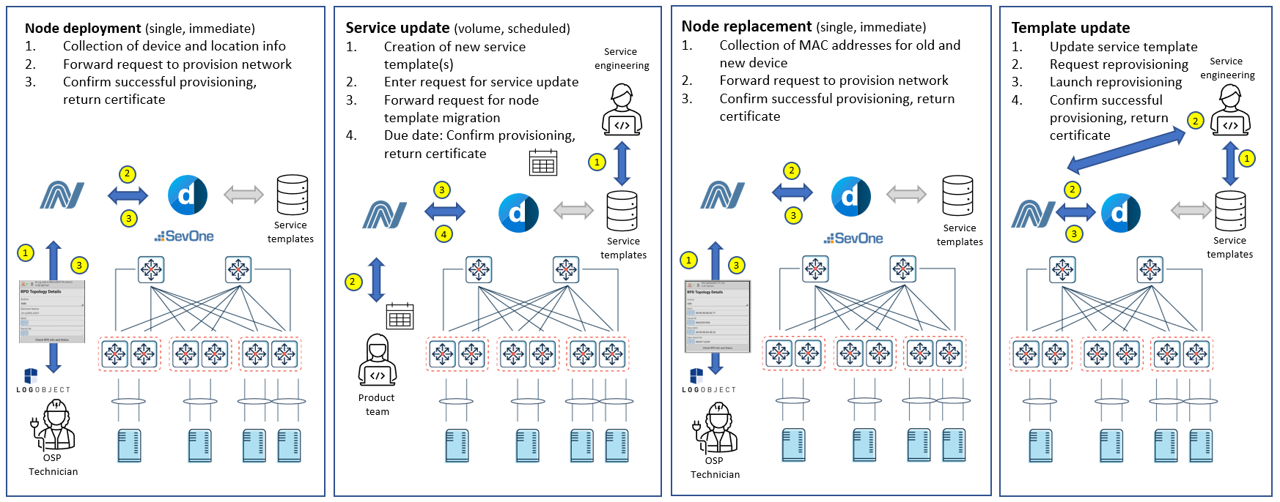

Here you can see an overview of the four different workflows implemented for this operator. Note the important differences between the different provisioning workflows, not only with respect to the team that triggers the process, but also when it comes to the elements involved (single or volume) and the timing (immediate or on schedule).

Here you can see an overview of the four different workflows implemented for this operator. Note the important differences between the different provisioning workflows, not only with respect to the team that triggers the process, but also when it comes to the elements involved (single or volume) and the timing (immediate or on schedule).

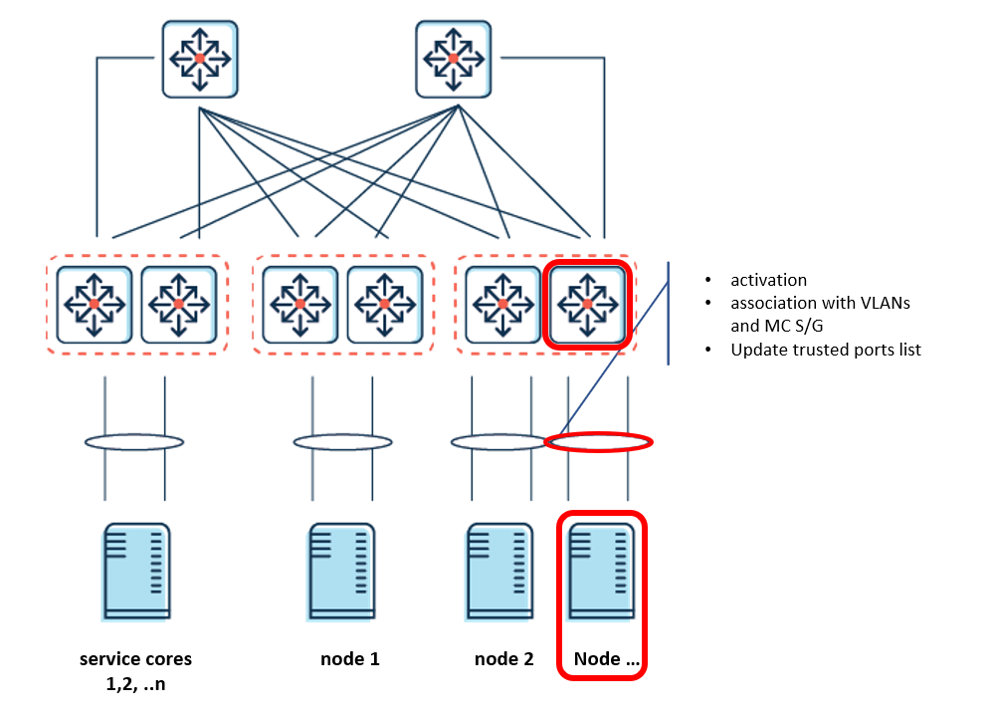

While this kind of provisioning activity is referred to as “RPD/RMD provisioning”, many of these “RPD/RMD provisioning workflows” also include important reprovisioning actions on the associated node leaf component of the converged interconnect network. The most obvious of this may be the activation of the port itself, but updates are also required to the trusted ports list for the backhaul interface, and the necessary joins need to be configured with the VLANs or MC S/G associated with the services provisioned on that node element.

While this kind of provisioning activity is referred to as “RPD/RMD provisioning”, many of these “RPD/RMD provisioning workflows” also include important reprovisioning actions on the associated node leaf component of the converged interconnect network. The most obvious of this may be the activation of the port itself, but updates are also required to the trusted ports list for the backhaul interface, and the necessary joins need to be configured with the VLANs or MC S/G associated with the services provisioned on that node element.

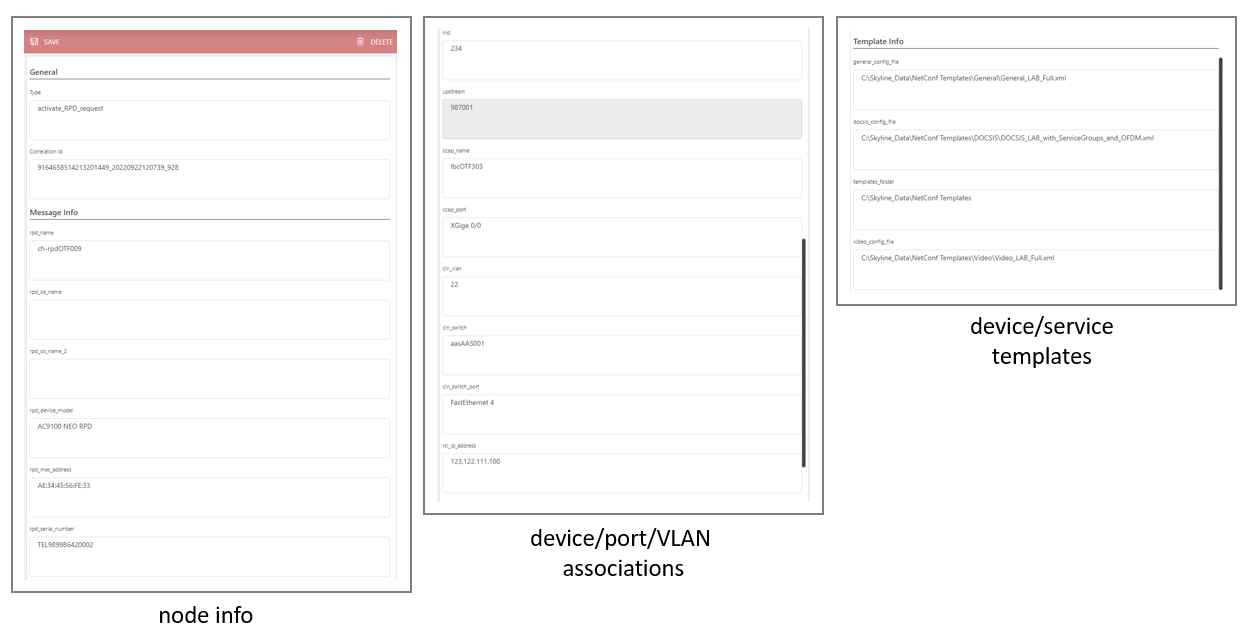

DataMiner Object Models are used to support the definition of the different workflows. These can easily identify subsets with information related to the workflow type (e.g. initial provisioning), node (e.g. type, serial, MAC, etc.), association (e.g. device, port, VLAN, etc.), and template (device, data, voice, video, etc.).

DataMiner Object Models are used to support the definition of the different workflows. These can easily identify subsets with information related to the workflow type (e.g. initial provisioning), node (e.g. type, serial, MAC, etc.), association (e.g. device, port, VLAN, etc.), and template (device, data, voice, video, etc.).

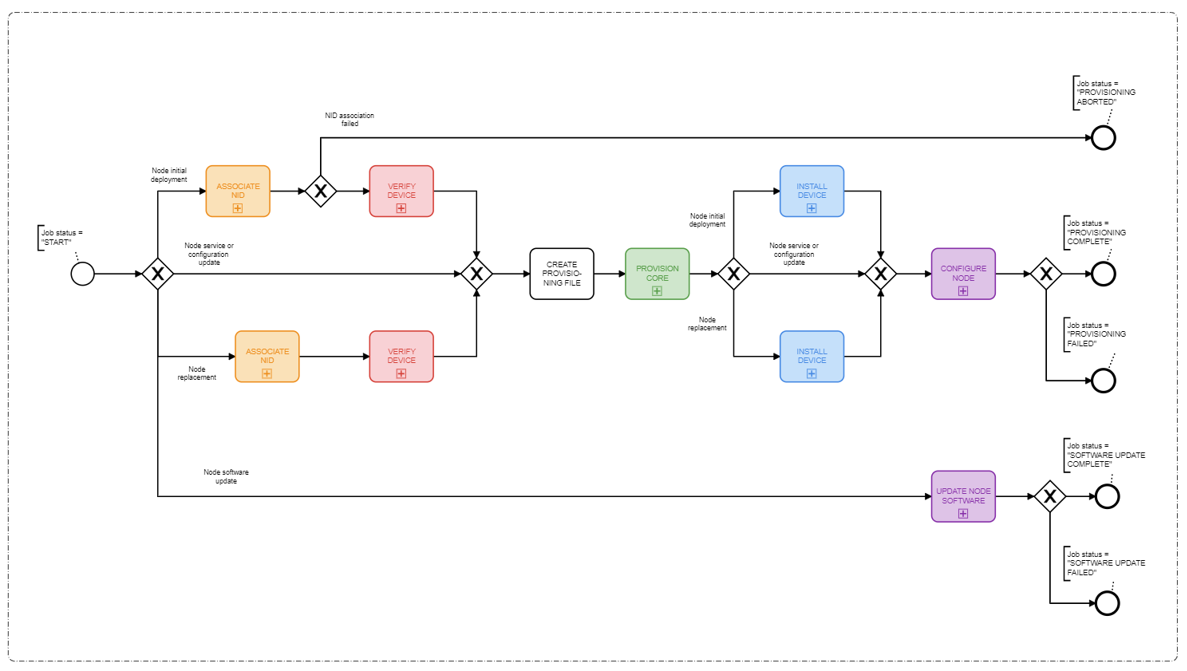

All workflows are implemented using the DataMiner Process Automation framework. While the industry-standard BPMN structure facilitates the integration into an even larger process, the highly modular design will also reduce the time and cost associated with testing and formal release of each of these workflows.

All workflows are implemented using the DataMiner Process Automation framework. While the industry-standard BPMN structure facilitates the integration into an even larger process, the highly modular design will also reduce the time and cost associated with testing and formal release of each of these workflows.